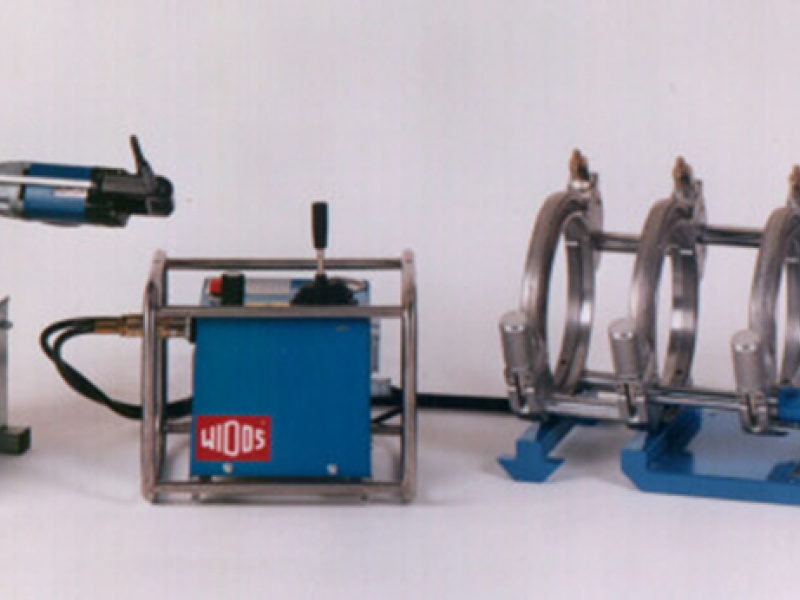

WIDOS 4400/4600/4900/4911/Weld It 250/Weld It 315

The most common devices for butt welding of pipes and fittings from PE, PP and PVDF for diameters from DA 50 to DA 355 mm, with hydraulic shift of clamping tool. Alternatively can be supplied with protocol unit SPA or control unit CNC, which enables to use it by gas pipelines instalation. As an advantage is very favorable weight and dimensions of the entire plant.

Weld It 250 and Weld It 315 versions are also available for a very good prices.

| Machine type |

WIDOS 4400 |

WIDOS 4600 |

WIDOS Weld It 250 |

WIDOS 4900 |

WIDOS Weld It 315 |

WIDOS 4911 |

||||||

| Range in mm | 50 - 160 | 75 - 250 | 75 - 250 | 90 - 315 | 90 - 315 | 90 - 355 | ||||||

| Basic machine | ||||||||||||

| Hydraulic power unit | ||||||||||||

| Electrical planer | ||||||||||||

| Heating element | ||||||||||||

| Protection box | ||||||||||||

| CNC or SPA unit | optional | optional | optional (SPA) | optional | optional (SPA) | optional | ||||||

| Transport case | ||||||||||||

| Reducer inserts | ||||||||||||

| Reducer inserts DA 50 | ||||||||||||

| Reducer inserts DA 63 | ||||||||||||

| Reducer inserts DA 75 | ||||||||||||

| Reducer inserts DA 90 | ||||||||||||

| Reducer inserts DA 110 | ||||||||||||

| Reducer inserts DA 125 | ||||||||||||

| Reducer inserts DA 140 | ||||||||||||

| Reducer inserts DA 160 | basic clamping tool | |||||||||||

| Reducer inserts DA 180 | ||||||||||||

| Reducer inserts DA 200 | ||||||||||||

| Reducer inserts DA 225 | ||||||||||||

| Reducer inserts DA 250 | basic clamping tool | basic clamping tool | ||||||||||

| Reducer inserts DA 280 | ||||||||||||

| Reducer inserts DA 315 | basic clamping tool | basic clamping tool | ||||||||||

| Reducer inserts DA 355 | basic clamping tool | |||||||||||

| Accessories | ||||||||||||

| Barcode reader | optional s SPA a CNC | optional s SPA a CNC | optional s SPA | optional s SPA a CNC | optional s SPA | optional s SPA a CNC | ||||||

| USB connector | with SPA and CNC unit | with SPA and CNC unit | with SPA unit | with SPA and CNC unit | with SPA unit | with SPA and CNC unit | ||||||

| SD memory card | with SPA and CNC unit | with SPA and CNC unit | with SPA unit | with SPA and CNC unit | with SPA unit | with SPA and CNC unit | ||||||

| Welding pass | with SPA and CNC unit | with SPA and CNC unit | with SPA unit | with SPA and CNC unit | with SPA unit | with SPA and CNC unit | ||||||

| Pipe data card | with SPA and CNC unit | with SPA and CNC unit | with SPA unit | with SPA and CNC unit | with SPA unit | with SPA and CNC unit | ||||||

| Operating software | with SPA and CNC unit | with SPA and CNC unit | with SPA unit | with SPA and CNC unit | with SPA unit | with SPA and CNC unit | ||||||

| Lifting device | ||||||||||||

| Heating element automatic control | optional | optional | optional | optional | ||||||||

The welding machine has a double clamping device with quick clamping on the fixed and on the movable side guided by 2 hydraulic cylinders. There are 2 flexible hoses with quick-action couplings for connection to the hydraulic control unit. The double clamping devices are screwed to the steel pipe frame. The outer fixed clamping tool can be easily dismounted by removing 3 screws in order to be able to weld at badly accessible places, e.g. in trenches or at branches of T-pieces. The remaining unit of three rings can be removed from the frame for use of repair work. The electric hydraulic unit - for moving the right-hand clamping device and for the exact control of the welding forces - has a pressure backup for supporting the welding force during the cooling down, 2 quick-action couplings as well as a digital pressure gauge for the exact indication of the pressure.

The planer is suspended in the guide shafts, has a chain drive in a closed aluminium housing, a security micro switch with lock and an automatic external chip removal.

The heating element is suspended in the guide shafts and anti-stick coated, has an electronical temperature control with digital display, control lamps, an on/off switch and a connection cable with shock-proof plug. The separating device prevents the heating element from sticking to the pipe after the heating process.

For the heat-protected storage of planer and heating element, a reception box is available. Smaller pipe dimensions can be clamped by means of reducer inserts depending on the pipe diameter. In addition, large and extra large reducer inserts or a combination of small, large and extra large inserts can be delivered.